Warehouse management solution consulting services…

Brilliant WMS gives Fast, Accurate Fulfilment Through Directed, Optimized Workflow, Utilizing Advanced Technologies.

Warehouse Management

Brilliant’s warehouse management software (WMS) is vital to improving the efficiency of a company’s warehousing operations. It can be customized to fit the needs of companies of any size. WMS system is fully expandable and scalable to include other modules. The warehouse Management System uses bar-coding which helps to extend the enterprise to the mobile worker while increasing operational efficiencies and enhancing your customer service.

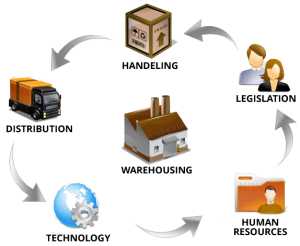

Brilliant’s warehouse management software covers the entire life cycle related to warehouse management. A barcode scanning system for a warehouse is a software application that supports the day-to-day operations in a warehouse. WMS programs enable centralized management of tasks such as stock locations and tracking inventory levels. No matter how simple or complex the application is, the goal of Brilliant’s WMS system is to provide management with the information it needs to efficiently control the movement of materials within a warehouse. Warehouse managers are a vital part of the supply chain process. They oversee the efficient dispatch, storage, and receipt of A wide range of goods. The core purpose of warehouse management system software is to control the movement materials’ storage within an operation and process the associated transactions efficiently. The detailed setup of directed packing, replenishment and put away are the keys to WMS. The basic logic will be used in combination of item, location, quantity, Unit Of Measurement (UOM) and order information to determine where to stock and where to pick.

Why you need Warehouse Management Software?

In warehouse management, an accurate understanding of your inventory, management of multiple warehouses likes to transfer stock between them with report generation. Order management is important to track and plan every process efficiently. Managing purchase orders, sales orders, creating packages and sending delivery updates with approval management automatically helps to improve efficiency and accuracy.

Warehouse Management Mobile App

Brilliant provides a mobile application for a warehouse management system. By using this application one can check GRN, Put In, Quality Check, Pick Up, Cycle Count and Transfer without getting logged in to the web application. Brilliant WMS Mobile App is very easy to use.

Technology For Work At Your Warehouse:

Receiving: Accelerate receiving processes by clearly identifying inventory and to improve tracking capabilities with or without inbound orders.

Storage: Automatically maintain and easily track material locations and we can combine storage locations capacity and release location capacity according to material size.

Order Allocation: The Order Allocation module assists with the allocation of inventory to customer orders. It allows incoming stock (purchase orders) as well as existing inventory on hand to be selected and allocated to customer sales orders and back orders.

Replenishment: Movement of inventory from product storage locations to pick up and shipment locations. The purpose of replenishment is to keep inventory flowing through the supply chain by maintaining efficient order and line item fill rates. The process helps to prevent costly inventory overstocking.

![]() Order Re-allocation: The order reallocation module assists with the reallocation of inventory to customer orders. It shares that has been allocated again.

Order Re-allocation: The order reallocation module assists with the reallocation of inventory to customer orders. It shares that has been allocated again.

Cross-docking: Benefit from the ability to either pick items or move them directly from the inbound dock to the outbound dock, thereby avoiding storage, replenishment, to reduce staffing and inventory carrying costs, space requirements and equipment needs.

Wave Planning: Gain operational efficiency and control by grouping orders into waves to be planned and released together.

Picking: Following wave planning makes released picks available to operators who can then pick orders quickly, without errors, using voice-directed, bar code-assisted, label, list, cluster or batch picking. It lets you eliminate lists, labels, scanners and ensure a safer, more efficient, real-time work environment.

Picking: Following wave planning makes released picks available to operators who can then pick orders quickly, without errors, using voice-directed, bar code-assisted, label, list, cluster or batch picking. It lets you eliminate lists, labels, scanners and ensure a safer, more efficient, real-time work environment.

Label Printing: A label (as distinct from signage) is a piece of paper, polymer, cloth, metal, or other material affixed to a container or product, on which is written or printed information regarding the product. Information printed directly on a container or article can also be considered labelling.

Label Printing: A label (as distinct from signage) is a piece of paper, polymer, cloth, metal, or other material affixed to a container or product, on which is written or printed information regarding the product. Information printed directly on a container or article can also be considered labelling.

![]() Warehouse and product maintenance: The maintenance means repair facilities; maintain equipment, products, buildings, and sites.

Warehouse and product maintenance: The maintenance means repair facilities; maintain equipment, products, buildings, and sites.

Kitting and packaging: In this process individually separate but related items are grouped, packaged, and supplied together as one unit.

Kitting and packaging: In this process individually separate but related items are grouped, packaged, and supplied together as one unit.

Packing: Use system-directed or assisted packing to support user-configurable container types including cartons, pallets, containers, and others with a variety of attributes including inner and outer dimensions, maximum product weight for a container, and minimum/maximum fill percentage parameters.

Packing: Use system-directed or assisted packing to support user-configurable container types including cartons, pallets, containers, and others with a variety of attributes including inner and outer dimensions, maximum product weight for a container, and minimum/maximum fill percentage parameters.

Shipping: Load contents on a trailer, issue a final release, and coordinate proper ship paperwork such as container pack list, master pack list, bill of lading, master bill of lading, and manifests.

Shipping: Load contents on a trailer, issue a final release, and coordinate proper ship paperwork such as container pack list, master pack list, bill of lading, master bill of lading, and manifests.

Inventory Control and cycle count: Multiple units of measure, lot control, and catch weights improve inventory accuracy and know what, where and how much inventory is in your warehouse using cycle count to regularly maintain the most accurate portrait of your warehouse inventory management system levels.

Multiple Inventory ownership: The ability to track multiple inventories, employee multiple businesses rules and manage billing for multiple customers improves 3PL and distributor efficiency.

Multiple Inventory ownership: The ability to track multiple inventories, employee multiple businesses rules and manage billing for multiple customers improves 3PL and distributor efficiency.

![]() Labor Management: Monitor and Schedule all direct and indirect labour and provide valuable feedback and status updates to workers and supervisors as activities are completed. Supports reasonable expectancies as well as engineered labour standards and profit from integrated time.

Labor Management: Monitor and Schedule all direct and indirect labour and provide valuable feedback and status updates to workers and supervisors as activities are completed. Supports reasonable expectancies as well as engineered labour standards and profit from integrated time.

Features Of WMS

- Customizable Dash Board

- Email Integration and Inbox

- Alerts Management

- Approval Management

- Import and Export Functionality

- Analytic and Reporting

- Advance Technology

- Customer & Vendor Management

- Bar-code / RFID based Tracking

- Activity Assignment and Tracking

- Track and Enhance Productivity

- Integrated Document Management

- Web Interface for 100% Real-Time Visibility

- FIFO, LIFO & product specific rules based picking

- High-Level Security based on Windows, SQL Server

- Improvement in Tracking and Utilization of Man-hours

- Auto Calculate Delivery Charges

- Mobile Apps to Capture Customer requirements

- Automated Email and SMS Facility

| Brouchers |

| Case Studies |

| Brilliant’s WMS |

| Contact For Free Demo |